woodworking shopmade homemade

recipro bandsaw

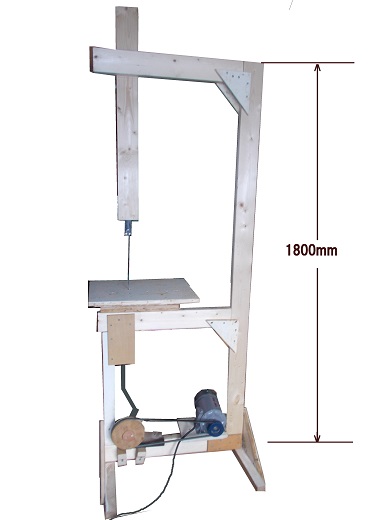

This project is to see if the simple machin can be replaced with the bandsaw. If it is possible, it is not necessary to build nor buy the expensive and complicated bandsaw. I don't know what is the neme of this machine, but I call it 'Reciprocate Bandsaw' in short 'Recipro Bandsaw'. As shown the following photo, this machine is just a big scroll saw machine, however blade stroke is around 200mm while scroll saw strokes only 20,30mm. And, in this unit doesn't employ two arms system which drives the blade back and forth.

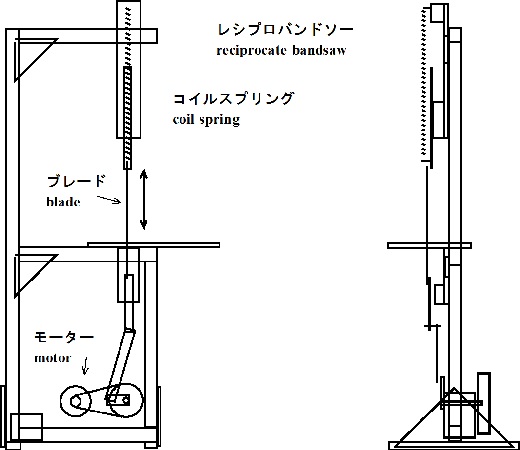

Please rifer to the next dwg. to see the details. The unit must be tall to secure the big stroke of the blade. The blade is driven by a motor through the pulley, belt, crank and sliding. Blade is fixed the ends of this sliding bar and upper sliding bar at the lower end. Upper sliding bar is pulled up by the coil spring so that enough tension is applied at the blade. The tension must be always enough strong at any position of the stroke, so I needed enough long spring. There fore upper guide and support must be enough large resulting the tall size.

I used the thick rubber band instead of the spring coil for this trial unit.

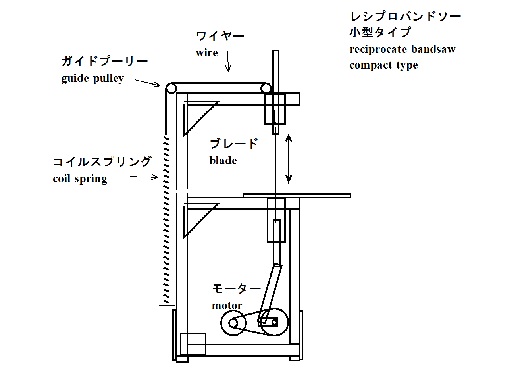

You can make this unit much smaller as the following dwg. Anyway you have to secure the stable and enough tension at the blade.

If this unit is useable instead of the bandsaw, the expensive and complicated bandsaw is not necessary to buy nor to build. I used almost scrap wood pieces and the motor is of the lathe for

I used the 200w motor of the small drill press first, but it didn't work. Power was too small.

Then I used 750w motor which is used in the lathe. This motor is 3p and rotation speed is controllable by the inverter.

Motor drives motor pulley, belt, wooden pulley, crank and sliding bar. This bar strokes the saw blade up and down.

Rotation of the crank change to straight stroke at this bar guide. Same guide is used for the upper sliding bar also.

Table and saw blade, same as the bandsaw.

The result is out of question. Too strong vibration is not controllable even at the much low speed. If the rotation is minimized and stroke is minimized, you can cut the work but it doesn't mean to replace with the bandsaw. Also it is quite dangerous if the work jump up to hit you. Unstable cutting is not acceptable.

I show here that I cut the wood piece on my shopmade bandsaw. Of cause I cut with no trouble. To get the point, this recipro bandsaw is out of question, and you can build the bandsaw by your self with almost same cost, effort, or can buy the bandsaw.

This project is to clarify if such simple machine is useable instead of the bandsaw or not. I thought such machine doesn't work before the project, and I was right.

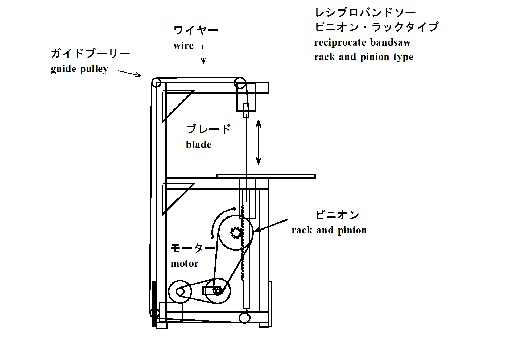

On the other hand, if you drive the blade by the rack and pinion as shown in the following dwg. to move the blade always at the same speed, and tension, more stable cutting would be available. However if you try this mechanism, the bandsaw is available with the same effort of building the bandsaw and almost same cost, I believe.

To The Next

To The Index

Return to Home